The tenets of lean construction include. Companies using lean construction practices are open to new ways of doing things and are always looking for ways to improve.

Pole Barn Construction Techniques Hobby Farms

The Southeast corners brace.

. Spaced trusses and no loft its best to space your wall studs 24 oc. Draw out the plans for your lean-to pole barn before building so you know what size lumber to buy and how large. How to Build a Lean-To Pole Barn Step 1.

Firstly steel building doesnt get harm easily. Leave equal overhangs on the front and back of the top beam. View Metal Barn with Lean-to.

Lean-tos can be a great way to get the most out of your post-frame building. Construction Methods If you want a spacious rustic abode with an airy yet cozy vibe it is hard to go wrong with a barn home conversion. Embed corner posts with temporary bracing.

The less expensive way is to fasten horizontal lath 24 oc house wrap if building to be. Hey Guys and Gals. Our prefab metal barns with lean-tos can be used for a much wider variety of uses than just agricultural purposes.

I have a existing Pole Barn 30 wide. You can also use these structures as a place to keep your animals safe. 10x32 Lean To Barn Aiken Sc.

Embed remaining posts bracing as you go. The steel of your lean to metal barn is rust-proof and proper treated chemically during fabrication so the building doesnt deteriorate and last longer. Our lean-tos are safely built to the existing structure adding a sizable area protected by a roof but otherwise open.

Elevate building pad 3 beyond footprint for drainage. Inset corner posts 1 12 to provide room for wall girts. 12x44 Building w10x44 Lean To Lancaster SC.

I want to make a 10 addition to the end of it. Use a circular saw to cut the top of the posts. Leave the braces on until you build the frame for the lean to roof.

Kits for All Purpose Buildings Gable Raised Center Aisle Monitor Gambrel Salt Shed Mono-Slope. 10x20 Lean to Barn Casper WY. The cable runs through the barn and emerges at ground level in a doorway at the opposite end.

10X50 Lean to Barn with 10x50 Lean to Winsor Sc. Traditional lean-to structures have. A beam in the center of the wall spans and braces an opening.

Building a pole barn is an ambitious task no matter what its purpose may be. Still if your lean to barn get damaged you can simply weld or replace the damaged panel of the barn structure. The other end of the beam rests in a hole dug in the ground.

Nailed treated uplift cleats to bottom of post. Choose from an 8 10 or 12 lean-to and enjoy extra protection from the weather. Over the past few years barn conversions have become very popular around the world.

Metal pole barn kits in 22 colors with a 40 year paint fade and chalk warranty just begin to describe the quality materials included in every pole barn package. This is the best way Iv. Step by Step 1.

The walls of the barn can be made of 29 gauge steel but it is a good idea to use heavier 26 gauge on the roof to minimize hail damage. Many builders also use the 26 gauge sheet metal for siding of large barns especially if they will be exposed to. To make the process less daunting and more cost effective weve compiled the following tips for a smoother pole barn construction project.

You can store all your larger equipment in the enclosed center section while keeping your smaller pieces of equipment under the lean-tos. Use post to beam connectors to lock them together tightly. A cable crucial to the process is centered in this beam.

Or should I use the Pole Barn poles and set them on the concrete that is already poured for the addition. Or if I bump it out should I use stick frame walls and set the trusses on that wall. Framing plan should show direction size and spacing of roof system purlins girts beams and header sizes.

Decide which side of the barn to leave open. Elevate building pad 3 beyond footprint for drainage. Metal Barn with Lean-to.

Barn Kits Pole Building Prices Horse Barns Pole Building Garage. How to set posts to build a pole barn all by yourself. When building a barn with 24 oc.

Step by Step 1. Fitting the support beam lean to addition Fit the beams to the top of the posts and plumb them vertically. The steel of your lean to metal barn is rust-proof and proper treated chemically during fabrication so.

How to install and set 6x6 treated posts for a pole barn all by yourself DIY. Lean construction offers a framework for improving the entire construction process from design through completion. Provide plan view of pole location spacing dimensions of the building.

A pole barn can come in many forms from a backyard garage to a horse barn to a storefront for a business. The other end of the beam rests in a hole dug in the ground. Indicate the locations of all window and door openings.

A lean-to can provide just the space you need for those things that you want to keep out of the weather but dont necessarily need to have inside the main part of your buildingOpen lean-tos are popular for machinery storage because of the additional space they offer with easy access. If you want to build a barn with stud frame and vertical wooden siding you must first fasten 58 CDX plywood sheathing on frame exterior then house wrap and finally your siding. As barn with lean to have no impact of rust and other.

Everyone is curious about whats going on. These popular pole barn options go back centuries when rafters would freely lean up against the wall of an existing building to expand it. OK should I make a Lean To or bump it out.

Adding A Lean To On A Pole Barn Part Ii Hansen Buildings

Pole Barn Hardware Pole Barn Nails Application Details

How To Build A Lean To Carport Howtospecialist How To Build Step By Step Diy Plans

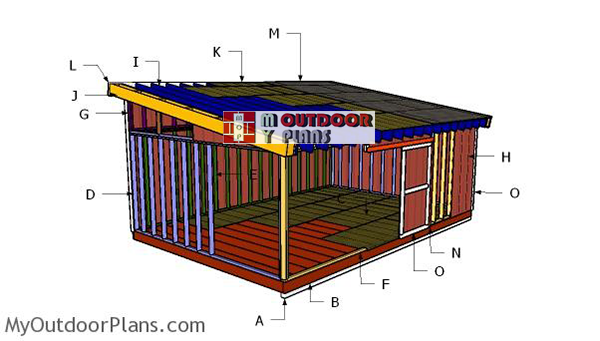

16x24 Lean To Shed Roof Plans Myoutdoorplans Free Woodworking Plans And Projects Diy Shed Wooden Playhouse Pergola Bbq

0 comments

Post a Comment